Solar & Storage Power Plant

Using solar energy and Tesla Powerpack to help hire & retain top talent, reduce energy costs, and stay ahead of competitors

The power plant is part of the company’s competitive strategy to:

Attract employees and vendors with a commitment to clean energy innovation

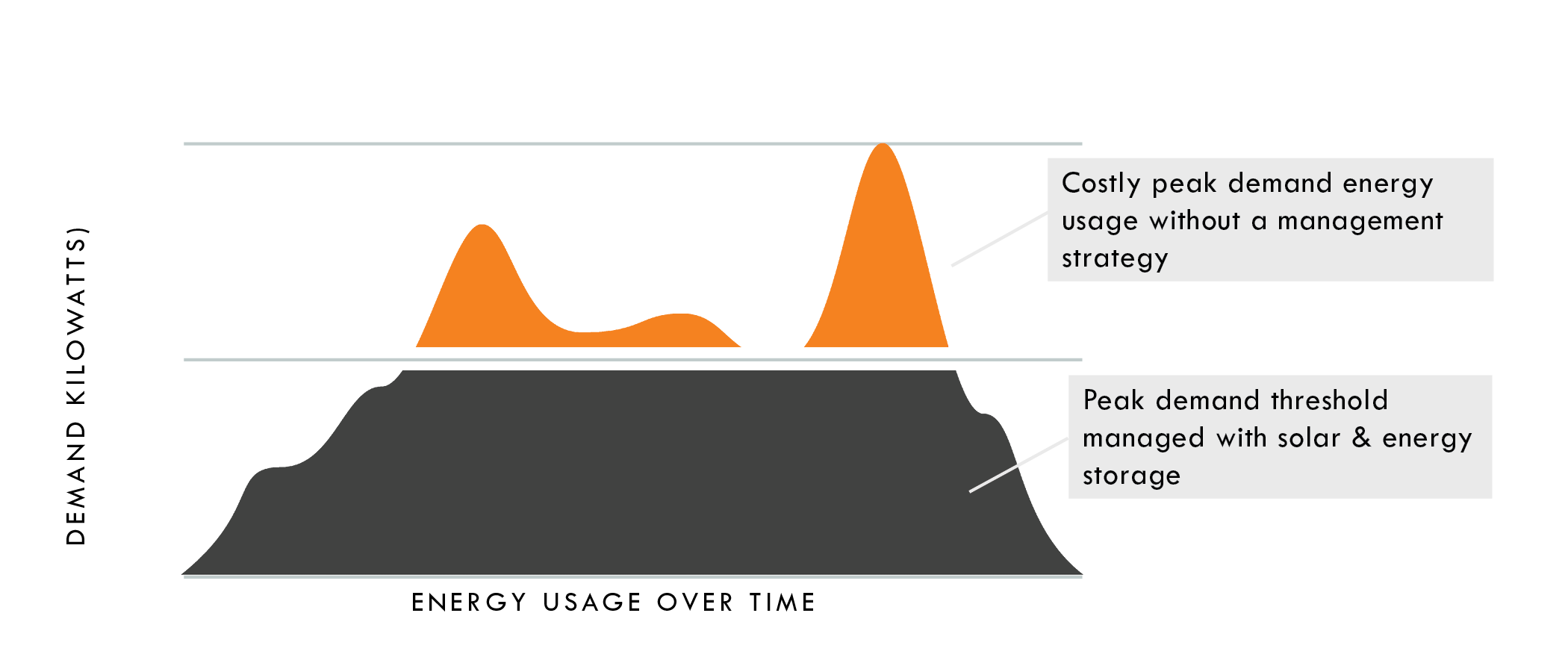

Reduce overall electricity costs with peak demand shaving

Combining technology, data, design, & machine learning to create an intelligent, future-facing energy system

I would consider solar a strategic investment for our future. We’re in it for the long haul. We’re in it for our customers, we’re in it for our employees, we’re in it for our community of Fairfield.”

–Lori Schaefer-Weaton, President, Agri-Industrial Plastics Company

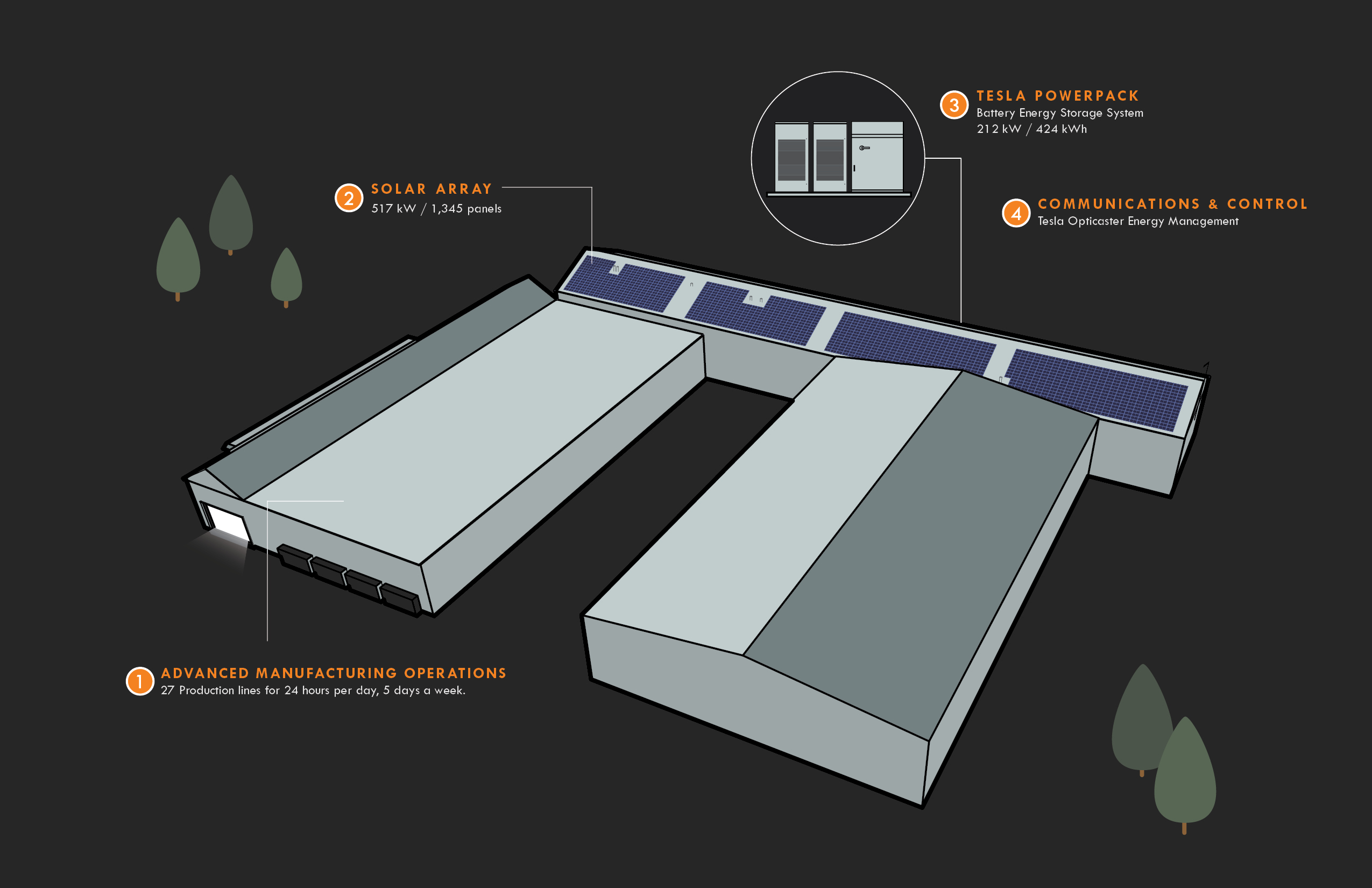

ADVANVED MANUFACTURING OPERATIONS

SOLAR ARRAY

TESLA POWERPACK

COMMUNICATIONS & CONTROL

Opticaster will use data from these projects to provide the initial algorithm to control the batteries. As AIP’s energy storage system gathers more data on its own performance and AIP’s load profile over time, it will use that data to further refine the algorithm.

Peak Shaving in Advanced Manufacturing

How Agri-Industrial Plastics Company is using solar plus battery energy storage to take control of its utility costs

DOWNLOAD TO LEARN MORE ABOUT:

- Unique challenges for large electric consumers with on-site renewables

- Managing energy loads for advanced manufacturing operations with solar & storage

- Intelligent use of AI in solar power plants including predictive algorithms, machine learning, control systems, and feedback

Recognizing the potential of solar and storage to reduce costs for Iowa’s manufacturing industry, we’ve partnered with the Iowa Economic Development Association (IEDA) and Fairfield Economic Development Association (FEDA) on our state’s first energy storage research grant studying the performance and applications of the technology used in the Agri-Industrial Plastic’s installation.

WHAT CAN SOLAR DO FOR YOU?

Find out more with an honest, no pressure consultation with our team of solar experts.

By clicking “submit”, you consent for Ideal Energy Inc. to contact you with the information provided. This consent is not required to make a purchase from us. We never share your information.

*Estimated 25 year utility savings are above and beyond the installed system cost with incentives, and are based on current utility electrical rates and predicted future utility rates. Production data is based on NREL and PV Watts.